Clocks Back but Hydro Progress is Forwards!

Despite the grotty weather during the period of October, progress made by our site civils contractor CT Construction Ltd has been quite positive although inevitably some slippage has occurred.

With the cofferdam in place (photo of this in last month’s newsletter) good progress has been made on the intake headwall and the inlet pipe trench. As soon as the concrete has been poured and set the Weholite pipe can be dropped in and the various lengths “welded” together. Just as a reminder, this pipe structure takes water from the river upstream of the Weir and feeds it into the Archimedes screw (via header tank system).

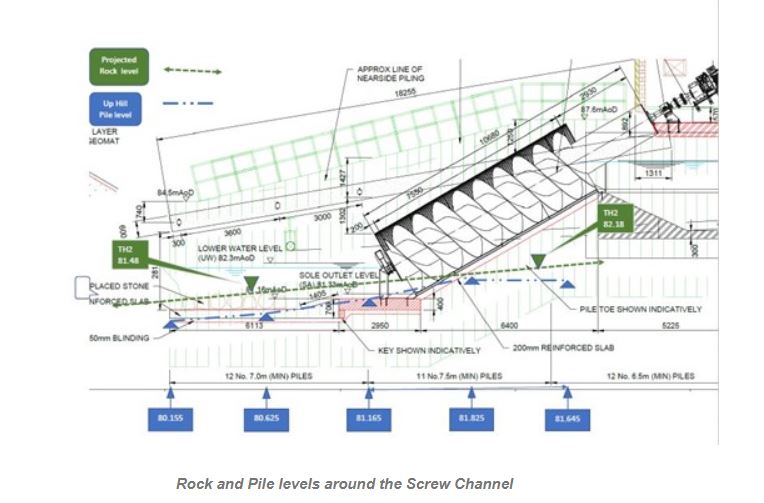

So, good progress on the inlet but what about the foundations and channel for the screw channel. Well, despite ground conditions making life difficult, the piling for the channel is basically complete although there remain some challenges with the rock level especially at the base of the screw. Some rock will need removing and the piles need to be pushed in further.

For those who like to see and hopefully understand the detail, the GA drawing showing the pile and rock levels overlay is shown below.

The photo shows the two sets of piles that form the basic channel for the screw. Unfortunately, the process of inserting the piles using a MOVAX (essentially a vibrating bashing attachment hanging off the digger arm!!) created a lot of noise. This carried quite a distance and disturbed and disquieted some of the residents in the local community. For this, we really apologise and will do our utmost in the future to keep noise to a minimum and give as much advance warning as possible.

So, in summary, good progress on the site construction but there are challenges to the programme due to persistent rain and rock levels.

Design of the Boardwalk that will facilitate education group and maintenance access to the generation site has been completed with the support of a structural engineer and a contract has been placed. The boardwalk structural design is such that it will support the weight and motion of a small tracked “digger” should any substantial ground maintenance work be required in the future, e.g. heavy log removal from the inlet. The boardwalk incorporates a sizeable plinth area at the site entrance (to safely accommodate a small education group), and a viewing gallery overlooking the Archimedes Screw. Construction will start in the next few weeks and hopefully be complete around the year-end.

The conceptual design for the proposed fish pass has been completed and a budgetary estimate put together for its detailed design and construction. This will now be passed to the Environment Agency for them to seek funding approval. It is not known whether this will go ahead, Landustrie has completed the manufacture of the Archimedes screw and it is ready for shipping. It is planned to arrive on-site at the end of November, exact plan for offloading and placing on the prepared foundations is yet to be finalised but we expect to use a pair of “synchronised” excavators at either end to do the lift and placement.

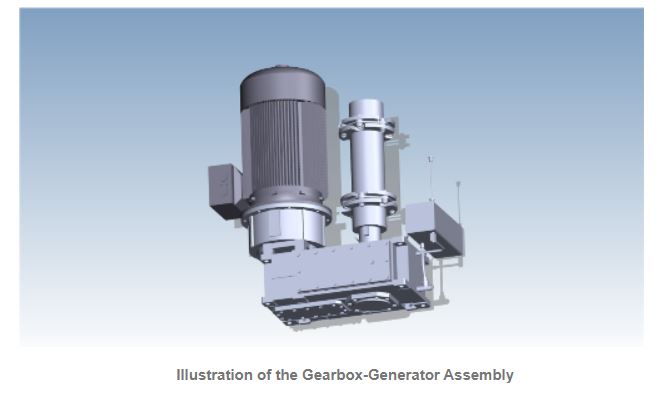

Flender in Leeds have completed the modifications to the gearbox/generator assembly and it will be shipped to site end of November (or when we have the screw in place and the powerhouse ready).

The testing of the Control Cabinet (Variable speed drive system, plc etc) has been started and control of generation capability into the grid from a test motor/generator set up has been satisfactorily demonstrated. We are grateful to Siemens for providing some space and facilities on the factory floor for this to be carried out.

The Archimedes Screw and the Gearbox coupled to the Generator, are the throbbing heart of the hydro system. With some water flowing in at the top, away we go, we have some electricity!!. Our system is rather more sophisticated and incorporates a Variable Speed Drive and an intelligent plc (programmable logic controller) control system that enables reliable generation over a wide range of flow rates whilst also ensuring we comply with EA regulations e.g. level of cosmetic water flow over the Weir. The Contol Cabinet, together with the gearbox and Generator have been generously donated by Congleton Hi-Tech company HMK. HMK is one of the UK’s largest and innovative Motion Control System suppliers in the UK and is also a key market channel partner of Siemens.https://www.hmkdirect.com/

The Variable Speed Drive is designed and manufactured by Siemens. Siemens in Congleton is one of the world’s leading designers and manufacturers of variable speed drives. Units manufactured in Congleton are shipped to just about every country in the world (at least 95% of the factory’s output is exported) and the Congleton factory is one of the most efficient, productive and innovative factories within the Siemens worldwide portfolio.

Available to download below are two articles that describe the operation of this “beating heart” of the Hydro. Starting with “Good old Archimedes” and his Screw used to irrigate the Hanging Gardens of Babylon, we also take a look some of the other forms of water to mechanical power conversion (including some of the basic maths to make it look good!!!!) and then follow up by illustrating how mechanical (rotational energy) is translated into electrical energy. What is a Variable Speed Drive and how does it work? and also how it is used to optimise the electricity generation over a wide range of flow rates are also illustrated.

We hope you will see from these articles not only how the system works but in keeping with the likes of companies such as Siemens and HMK, our Hydro System maintains Congleton’s High Tech reputation. We hope you enjoy reading them.

With a small Volunteer group (thank you all) the Education Programme recently kicked off with a “ZOOM” hosted Induction and programme introduction. Part-funded by a grant from the Regional Communities Energy Fund, the detailed Education programme and its various modules that support its core Objective of creating “Green Champions to better inform the future generation of the importance of our environment and its sustainability” will be the subject of a future article. In the meantime, we need to increase the breadth and depth of the team by having a knowledgeable KS2 person join us (existing/retired primary school teacher or person with equal knowledge) and also a Volunteer who would be able to help develop (and maybe present) some of the technology-based activities that the hydro system enables. If you are interested, we would love to hear from you, please drop an email.

Whilst on the subject of Volunteers, we again would like to thank all of you who have expressed interest in pursuing the various opportunities and helping run and maintain the system. Before long we will be able to better articulate these various opportunities via “Role Descriptions” and can then enter into a proper dialogue with yourselves. Again in the meantime, we are in need of help to install some of the site electrics (site wiring—mostly low voltage and powerhouse ancillary electrics eg control cabinet connections, 13A sockets for kettle !!! etc), we would be grateful for help from a practising/retired electrician or somebody who has good electrical knowledge. If you can help please contact us.

We hope you find the attached articles of interest and informative. If you require further information or have any questions please contact Paul Guymer and Mervyn Sara via email.

As with previous newsletters, we hope you have found this edition to be of interest and informative. We would welcome any feedback and suggestions for improvement, future topics etc.

Finally, in these uncertain times and November’s lockdown, with hands-on hearts, we hope our programme will not be impacted but in reality, we do not know what is hiding around the corner to bite us!! We hope for favourable conditions and fine weather!

So, until next month please take care with all you do and please ensure you stay safe.

Recent Comments