Last month’s storms of Eunice and Franklin seem to have blown all the rain away and for the last few weeks it just been miserably cold but no rain. Hopefully, the adage of “March winds and April Showers bring forth May Flowers” will hold true and we’ll start to get some decent rain—although hope this does not spoil any Easter celebrations you may have!

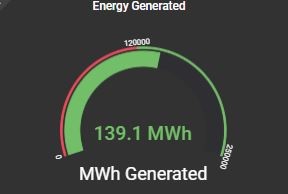

Despite the sparsity of rain, as you can see below the cumulative generation figure is still reasonable.

Cumulative Energy Generated to End of March 2022 below.

As maybe a matter of interest the saying “April showers——-” can be traced back to the 1500’s English Poet Thomas Tucker (Thomas Tusser – Wikipedia). Back then he wrote,” Sweet April showers do spring May Flowers”. In the UK, the month of April brings huge weather swings with the jet stream lifting northward at the start of spring. Maybe it’s a reminder that even the most unpleasant of things, in this case, the heavy rains of April, can bring about very enjoyable things indeed—even an abundance of flowers in May!!

A core reason that we manage to generate power, albeit low amounts, during periods of little rain and the consequent low River Dane levels is our use of a Variable Speed Drive. However, this is not continuous generation as you all know we have to maintain a minimum flow of 6mm over the Weir’s head. If the water level drops below this, we put the system on standby—close the sluice gate, stop the screw and apply the brake. Once the water level over the weir has recovered, we can start again. Our “start again” level is currently set at 9mm. The plot below shows the cyclic nature of this “low water level” start-stop mode of operation. The eagle-eyed amongst you will notice the river level orange curve rises as the sluice gate closes. The green curve is the corresponding forebay tank level.

Of course, each time we shut down and startup puts some degree of “strain” on the system components —sluice gate, gearbox, brake etc. this is an area of the hydro operation that will be looked at over the coming months (see below for some related thoughts).

Last month’s comments about the “perils”! of using E10 fuel in older cars brought many comments—thank you for these. One response contained some feedback from a Classic Car Journal:

“Regarding E10 fuel, another concern is condensation. This can happen in the fuel tank, as any space not filled up with fuel will be taken up by air containing water vapour. Apparently, the additional bio-ethanol content in E10 prefers to mix with water as opposed to petrol (useful!!) and where there is sufficient of both, it leaves the petrol and combines with the water to form a separate layer at the bottom of the fuel tank. The fuel line then picks up this watery mixture and pumps it straight into the engine. It is believed that either a full tank of fuel, leaving a minimum air gap for condensation to form, or a ‘near’ empty tank of fuel, reducing the bio-ethanol content in the tank, will minimise the risk of this happening. Obviously, if the vehicle is used all year round and the fuel is being constantly used and replenished this reduces the risk. However, with current fuel prices, you may need to rob a bank to do so!”

The passing of March has brought about the end of the bare root planting season. Ruth Benson and the team of volunteers have worked over the winter period and have done a great job with almost 300 native trees being planted. Ruth is also a master of CAD, and her site planting graphic is shown below. (PDF copy attached for those that might want to view finer detail)

Well Done Ruth and Team

In last month’s Newsletter we noted a comment from Dave regarding spurts of water emanating from Archie. As a reminder, it is copied below together with the thoughts of your esteemed hydro team!!

One of the visual impacts of low levels is a reduction in the volume of water feeding Archie and therefore the speed is reduced (but we continue to generate). This sometimes causes water turbulence and water splashing out of the vanes into the side channels. Some observant people like Dave, noticed this and were worried that Archie was broken! who sent us this email:

I went past the Havannah Weir yesterday. Although the site is not really visible from the road it seemed there may be a problem. I could see that there were spurts of water coming out the side of the Archimedes screw on the right-hand side as you look from the road and about halfway down the length of the screw.

I do hope it isn’t damaged.

Hello David

Thanks for your note.

You are observant!!

Yes, there are spurts of water “erupting!!” from the Archimedes Screw but No, it is not broken!

The geometry of the screw is designed for an optimum speed of 30rpm and when operating at (or somewhere near this speed) there is very little overspill of water.

However, Congleton Hydro uses a Control System with a variable speed AC drive at its core. This means that we can continue to generate electrical energy at very low river water levels (providing we maintain the agreed cosmetic level of 6 cm flow over the Weir head.

One of the “negative consequences” of this, is at very low operating screw rotations we do get water splashing/turbulence rather than a more laminar/smooth transit of the water down the screw. Whilst visually it looks like water wastage, in reality we lose very little electrical power generated.

Hope this gives you confidence that Archie is alive and well—although a drop of rain would be useful to satisfy his appetite.

Thanks again for your interest and getting in touch with us.

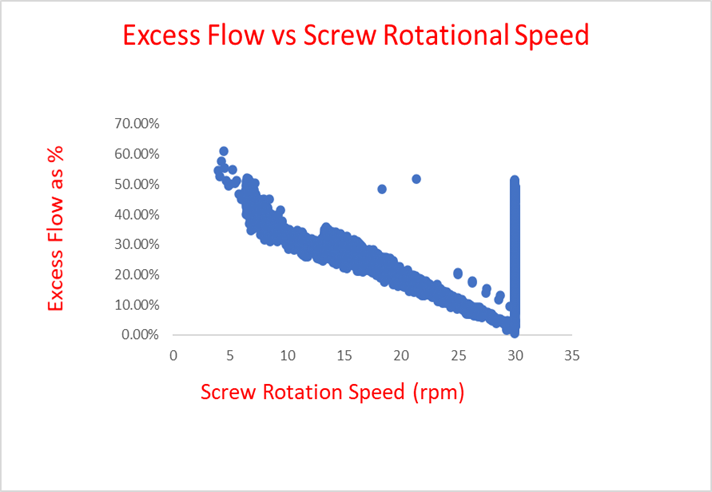

In fact, this is an issue that has been giving us food for thought since the beginning of operation After several months of operation at high and low flow levels we are starting to accumulate some good data. Paul Guymer, to his wife’s chagrin and despair, enjoys playing with data (actually he is rather good at it and fancy graphs as well!) and has led the team to give it some more thought.

The theory goes something like this:

We can estimate the flow through the screw in two ways and a comparison of the results will give us some insight as to how much excess water is flowing:

First the ideal flow for a given rotational speed = [(design flow- leakage) x actual speed/ design speed] + leakage, where the leakage between the trough and the screw is taken to be a constant 4% of the design flow.

Second the actual flow can be estimated based on the hydraulic losses in the 30m long intake pipe (i.e., measured head loss between the intake and the forebay tank).

The Excess Flow is then given by the Actual Flow minus the Ideal Flow which if plotted looks something like this:

We obviously need to be cautious about this result as there are uncertainties involved in the estimation of the actual flow. However, the fact that we observe the least amount of excess flow when the screw is running just below its design speed (29 rpm) gives some corroboration.

This Excess Flow relative to screw speed also manifests itself as lower than expected “water to wire” efficiency, particularly at low flow rates (corresponding to low screw speeds) as can be observed from the plot below.

There are also similar effects at maximum speed when the water level in the river begins to rise above the control point.

The underlying reason for this is thought to be that the excess water in the screw, which results in spillage over the barrel from one bucket to the next as well as some minor losses over the sides of the trough, does not create significant additional torque.

The remedy for this would seem to be obvious; Make the screw run at a higher speed so that the actual flow more closely matches the ideal flow. However, this isn’t possible under the current arrangement as a higher screw speed would simply draw more water into the intake with the result that the flow over the weir would drop below the minimum reserve required by the Environmental Agency. (0.5m3/s)

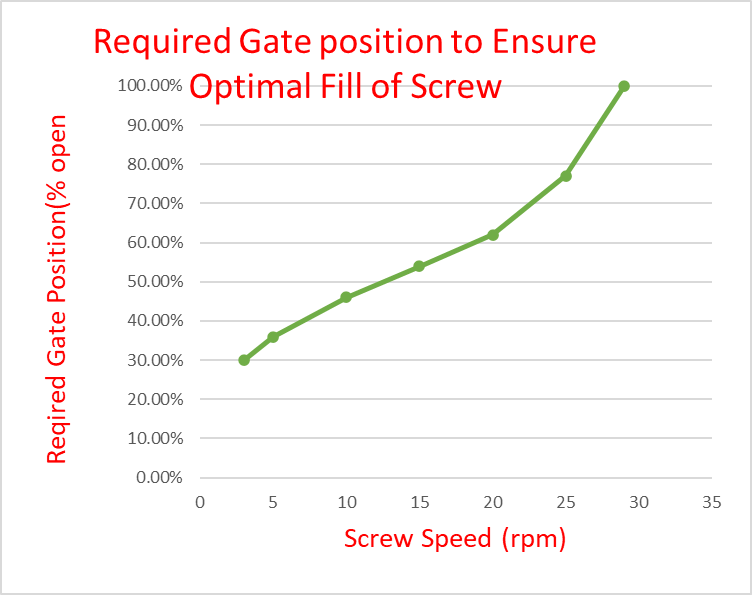

A possible answer is therefore to modulate the intake gate position (which is normally fully open under the current arrangement) and thereby maintain the level of the forebay tank and the screw at an optimum point. The required gate position for a given screw speed in order to maximise efficiency has been estimated as to as follows:

There are various assumptions built into this prediction which will need to be refined based on actual operating experience. Once we’ve tested (and proven) the theory we might consider adding an additional control loop that automatically adjusts the gate position

Then again all of this could be total speculative rubbish but as a minimum, it would be interesting and perhaps profitable to test it out.

Then again all of this could be total speculative rubbish but as a minimum it would be interesting and perhaps profitable to test it out.

The Practice So, that’s the theory and speculation but what about practice? Well, a week or so ago, the sun was shining and under a gorgeous blue sky we decided to “have a play” at only partially opening the sluice gate and see if there was any impact. The screw was running at about 3 rpm and generating about 3kW at the time.

In fact there was an impact—we did get some extra power (stable operation at 10KW instead of 3KW), hardly any water leakage and a remarkably quiet screw. So what happened? As expected, the screw speed increased to restore the water flow back to its original flow rate which had decreased as a result of the increased head loss across the partially closed gate. The operating forebay tank level dropped. However, this did not result in diminished torque. Since power is the product of screw torque and rotational speed, more power was generated.

“Having a Play” is the operative phrase—bits of string and tape to measure gate depth and so on. But the results are encouraging enough for some serious work to be done in the weeks after the Easter break—one of the key issues being how do we reconfigure the control system, do we use forebay level instead of the Weir? (We would still need weir 6cm as absolute backstop) Hopefully some positive results to report in one of our next newsletters

David, when you are passing in a month or so’s time, maybe you will give us some feedback on “low-flow water spillage” or hopefully its absence!!!

Last month, you may recall, we were all set to dump our camera system in the river and acquire a new system. But perseverance pays off—it was the dodgy power supply of the cctv control box. Replacing with a slightly beefier unit fitted with an inline filter has given us a working and more importantly reliable system. We even have TrashCam working!!

TrashCam view of water Intake—allows us to remotely check for blockages.

Building on the success of Congleton Hydro (well we reckon so far, it’s successful!!!), the team behind it have secured £100K funding to develop a brand-new renewable energy scheme. The grant funding is from RCEF –Regional Communities Energy Fund. RCEF The RCEF is a multi-million-pound programme that aims to support rural communities in England to develop renewable energy projects, which provide economic and social benefits to the community. It is a joint activity between the Government Departments of BIS and DEFRA—–Business, Energy and Industrial Strategy, Department for Environment, Food and Rural Affairs.

RCEF is run by 5 regional Local Energy Hubs. The hubs are split by Local Enterprise Partnership Regions (LEP’s —–The LEP Network | Supporting all 38 LEPs across England) our funding comes via the Northwest Hub.

If you google RCEF you might actually get the Rice Competitive Enhancement Fund (Accomplishments – Mechanization Component | Department of Agriculture – Rice Competitiveness Enhancement Fund (da.gov.ph)) interesting reading but nowhere near as exciting as Renewable Energy!!—amazing what you learn from our Newsletters!!!!

Further info in a future newsletter but in the meantime please take a look below and respond to this great opportunity to join a winning team (PDF also attached).

Build on the success of a community energy project

Volunteers needed for a new renewable energy initiative in Congleton

Following the successful construction and commissioning of a Hydroelectric Project at Havannah Weir, more commonly known as “ARCHIE”, the team behind it have secured grant funding to develop a brand-new renewable energy scheme. This time the goal will be to generate power from both hydro and solar sources. The hydro scheme will be located beside the weir near Congleton Park. The solar arrays will be positioned on the roofs of suitable private and public buildings around Congleton. Apart from generating carbon free energy, the scheme will provide a focal point for promoting sustainability within the community and an educational resource. Surplus funds from selling the electricity will be directed into community projects. £4,000 has already been made available from the first project after only 5 months of operation.

To administer this exciting new project a new Community Benefit Society (CBS) will be formed. While building on the expertise and knowledge of those involved in the development of ARCHIE, this new CBS (to be known as Dane Valley Community Energy-Congleton Park or DVCE-CP for short) will be financially and administratively independent of DVCE Ltd.

Consistent with that aim we are looking for new blood to form the implementation team. More specifically we need individuals who are willing to be appointed as committee members or directors of DVCE-CP, filling the roles of Company Secretary and Treasurer and other roles. You would be joining a team of highly motivated individuals who have enjoyed each other’s company and pursuing a common goal for the good of the community.

Those appointed must be committed and able to share the responsibility of driving the project development forwards with assistance from an experienced Renewable Energy Consultant, already selected by the current DVCE team. The existing DVCE team will also be on hand to advise. The project development phase will involve feasibility and engineering studies, environmental impact studies, planning and Environment Agency applications, a business case development and finally a public share offering.

Those who are interested in getting involved should make themselves known by sending an email admin@congletonhydro.co.uk with some background information about themselves

Volunteers are Needed in the following areas:

- Secretary

- Treasurer

- Electrical Design

- Mechanical Design

- Civil Construction

- Publicity

- Bookkeeping

- Construction work, Etc.

Etc.

Finally, a reminder to Members/Investors that the DVCE Congleton Hydro AGM is being held on Monday April 25th at 7pm. You should already have received an invite and if you have not already done so, would you please notify via admin@congletonhydro.co.uk your intention to participate. A zoom link will be sent out shortly before the event.

As with previous newsletters, we hope you have enjoyed reading this edition and found it to be informative. We really enjoy and value your feedback, suggestions, and comments—please them coming via info@congletonhydro.co.uk

We hope you have an enjoyable Easter and hope you manage to dodge those welcome April showers!!!

With Best Wishes from The Congleton Hydro Team.

Recent Comments